Beautiful Plants For Your Interior

PEB Buildings & Container House Manufacturer | Aludream

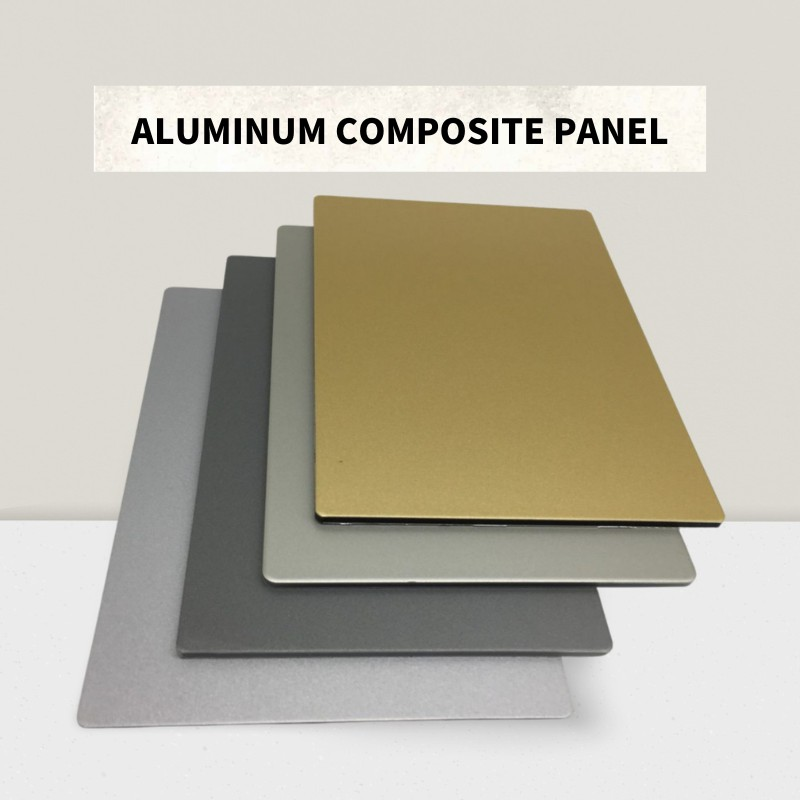

What makes Aluminum Composite Panels more than just a panel?

Choosing the right cladding is tough. You worry about budget, looks, and safety. A cheap choice now could mean costly repairs, a faded facade, or a safety hazard later.

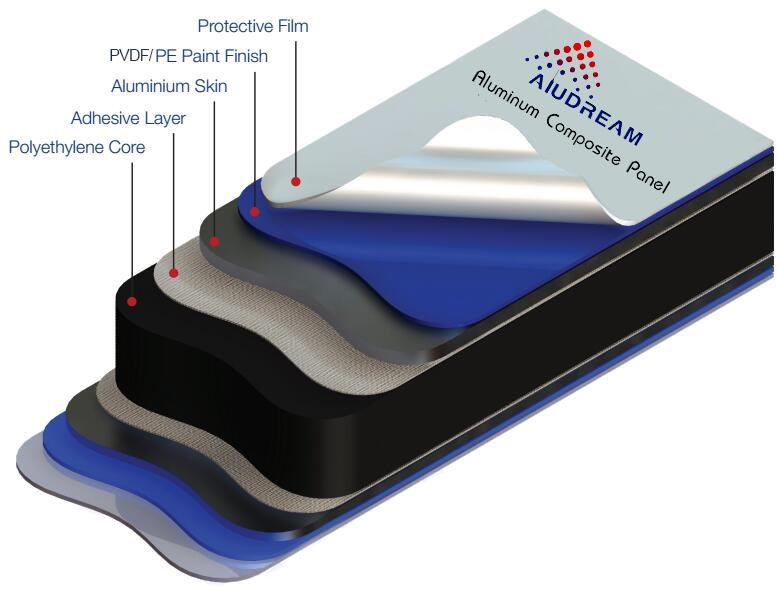

Aluminum Composite Panels (ACP) offer a unique combination of advantages. They are lightweight, incredibly flat, and easy to fabricate. This versatility, combined with a wide range of finishes and excellent durability, makes them a superior system material for modern construction, ensuring safety, aesthetics, and long-term value.

I’ve seen many buyers in my career focus only on the price per square meter. They treat Aluminum Composite Material (ACM) like a simple sheet good. But I always tell them they are missing the bigger picture. Professional buyers understand they aren’t just buying a panel; they are investing in the reliability of their project for the next decade. The real value of ACP lies much deeper. Let’s break down the key advantages that define it as a complete system material.

How do ACP sheets contribute to building safety?

Building fires are a major concern for everyone. Choosing the wrong cladding material can introduce a huge and unacceptable risk. Non-compliant materials can spread fire rapidly, endangering lives and property.

High-quality ACP sheets contribute to safety through their fire-retardant (FR) core options. These panels are specifically engineered to resist combustion and limit the spread of flames. This is a critical feature that helps buildings meet stringent fire safety regulations, protecting both the structure and its occupants.

When we talk about safety, the core of the panel is everything. It’s a detail that is completely hidden after installation, but it is one of the most important decisions you will make. At our company, we offer panels with different core materials, and understanding the difference is key to specifying the right product for your project. A standard panel often uses a Polyethylene (PE) core. While suitable for some applications, it doesn’t offer fire resistance. For multi-story buildings or projects with strict safety codes, a Fire-Retardant (FR) core is essential. This core contains mineral fillers that actively work to suppress a fire. It’s a choice that directly impacts the building’s overall safety system. We ensure our products meet high standards, with approvals like SGS Fireproof Grade B1, to give our clients peace of mind. This isn’t just a feature; it’s a fundamental commitment to safety.

| Core Type | Composition | Fire Performance | Recommended Use |

|---|---|---|---|

| Standard (PE) | 100% Polyethylene | Combustible | Low-rise buildings, signage |

| Fire-Retardant (FR) | Mineral-filled Core | Resists flame spread | High-rise buildings, public spaces |

Why do architects love the look of ACP sheets?

You want a sleek, modern building facade. But large metal panels often warp or look uneven. This “oil canning” effect can ruin the building’s aesthetic and make it look cheap.

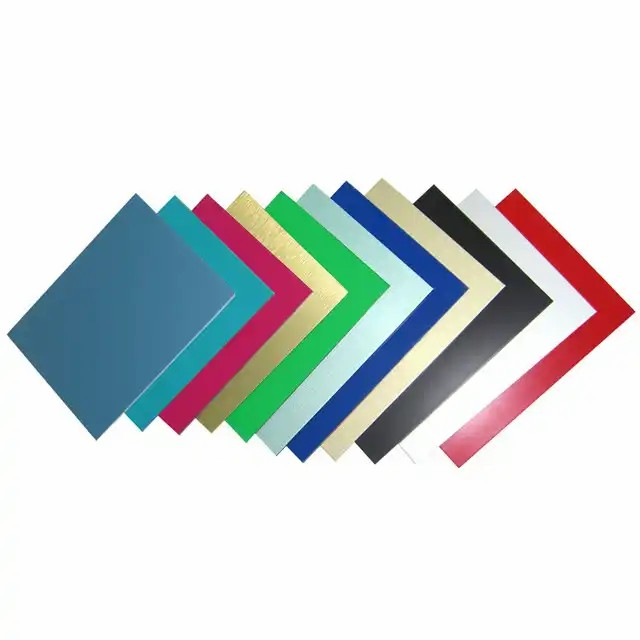

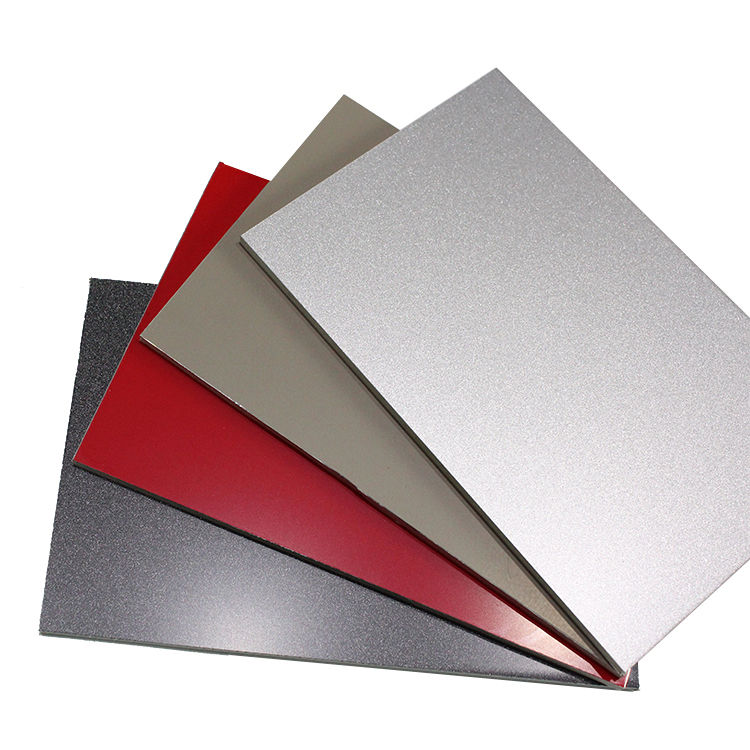

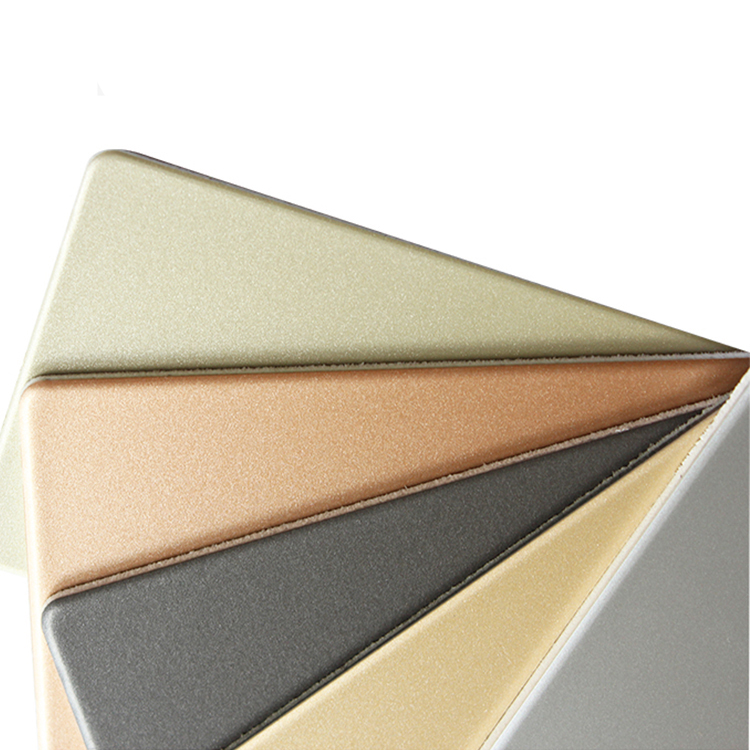

Architects prefer ACP sheets for their superior surface flatness and incredible design flexibility. The composite structure prevents warping, ensuring a smooth, premium look. With a vast range of colors, finishes like metallic or wood-grain, and custom options, ACP allows for unparalleled creative freedom.

The first thing people notice about a building is its appearance. As a manufacturer, I take great pride in the visual quality of our panels. The secret to ACP’s perfect flatness is its sandwich structure. Two thin aluminum sheets are bonded to a core material. This creates a rigid yet lightweight panel that stays flat, even in very large sizes. It’s a stark contrast to solid metal sheets that can easily buckle. But flatness is only half the story. The surface finish is where the design possibilities truly open up. Our three coating lines allow us to produce a massive variety of looks. We can create vibrant solid colors, shimmering metallic finishes, and even realistic wood or stone patterns. This versatility means architects aren’t limited in their vision. They can design a facade that is both visually stunning and structurally sound, making the panel an integral part of the building’s design system.

Common ACP Finishes

- PVDF Solid Colors: For a clean, uniform, and timeless look.

- Metallic Finishes: Adds depth and a modern, high-tech feel.

- Color Veined / Stone Patterns: Mimics the look of natural materials like marble or granite.

- Advertisement & Signboard Panels: Optimized for digital printing and vibrant graphics.

Will an ACP facade stand the test of time?

Your new building looks fantastic on day one. But what will it look like in ten years? Fading, chalking, and corrosion can quickly degrade a building’s appearance and lower its value.

Absolutely. ACP facades are built for longevity. The panels are coated with high-performance PVDF paint, which provides excellent resistance to UV radiation, weathering, and pollution. This ensures the color remains stable and the surface stays clean for decades with minimal maintenance.

When a client invests in a facade, they are investing in the building’s future. The long-term durability is non-negotiable. The key to an ACP panel’s longevity is the quality of its coating. We primarily use PVDF (Polyvinylidene Fluoride) coatings, which are the gold standard in the industry. This type of paint system is exceptionally resistant to the things that break down lesser coatings, like harsh sunlight, acid rain, and air pollution. A high-quality PVDF coating will resist fading and chalking, keeping the building looking fresh and new for many years. This is part of our commitment to quality, backed by our ISO9001 certification. A durable facade is more than just a panel; it’s a system for preserving the building’s value and reducing future maintenance costs. A cheaper panel with an inferior coating might save money initially, but it will cost much more in the long run through repainting or replacement.

| Coating Type | UV Resistance | Warranty (Typical) | Best For |

|---|---|---|---|

| Polyester (PE) | Good | 5-10 Years | Interior, Signage |

| PVDF | Excellent | 15-20+ Years | Exterior Facades, High-exposure areas |

How can ACP sheets reduce project costs and timelines?

Project delays and high labor costs can destroy your budget. Heavy, difficult-to-handle materials are often a major cause. They require more workers, specialized equipment, and more time on site.

ACP sheets reduce costs through their lightweight design and ease of fabrication. They can be easily cut, bent, and routed on-site with standard tools. This simplifies installation, reduces structural load requirements, and shortens construction timelines, leading to significant savings.

I always remind buyers that the material cost is only one part of the total project cost. The installation cost is just as important. This is where ACP provides a massive advantage. An ACP sheet is significantly lighter than a solid aluminum panel of the same thickness, not to mention traditional materials like stone or concrete. This has several benefits. First, it reduces the load on the building’s structure, which can lead to savings in the foundational and structural frame itself. Second, the panels are much easier for workers to handle on-site, often without needing heavy lifting equipment. Third, they are incredibly easy to fabricate. You can cut, groove, and fold them into complex shapes using common woodworking or metalworking tools. This allows for rapid installation and custom detailing right on the job site. This efficiency is why we see ACP as a system material. It doesn’t just cover the building; it actively helps make the entire construction process faster and more cost-effective.

| Material (approx. 4mm thick) | Weight (kg/m²) | Handling & Installation |

|---|---|---|

| Aluminum Composite Panel | 5.5 – 7.5 | Easy, fast, standard tools |

| Solid Aluminum Sheet (3mm) | ~8.1 | Heavier, requires more labor |

| Natural Stone Cladding (20mm) | 50 – 60+ | Heavy, specialized equipment needed |

Conclusion

In conclusion, choosing ACP is not just buying a panel. It’s an investment in your project’s long-term safety, beauty, durability, and overall cost-effectiveness.

Get a quote for prefabricated house

Select the product you like and our staff will contact you within 12 hours and send you the catalog and quotation.